FAC FEATURED PRODUCT

Introduction: The Imperative for Digital Confidence

The aerospace manufacturing sector operates under a mandate of zero tolerance for error. Producing critical structural components—often machined from high-value exotic materials such as titanium alloys and advanced composites—is inherently high-risk and high-cost. In this environment, where material expenditure is immense and the hourly rate of sophisticated machine platforms (e.g., 5-axis and mill-turn centers) is significant, any minute lost to manual prove-outs, unplanned downtime, or catastrophic collisions translates directly into substantial financial loss and delays in complex supply chains. Achieving absolute confidence in the numerical control (NC) program before the tool touches the material is not merely beneficial; it is a fundamental requirement for risk management and operational viability.

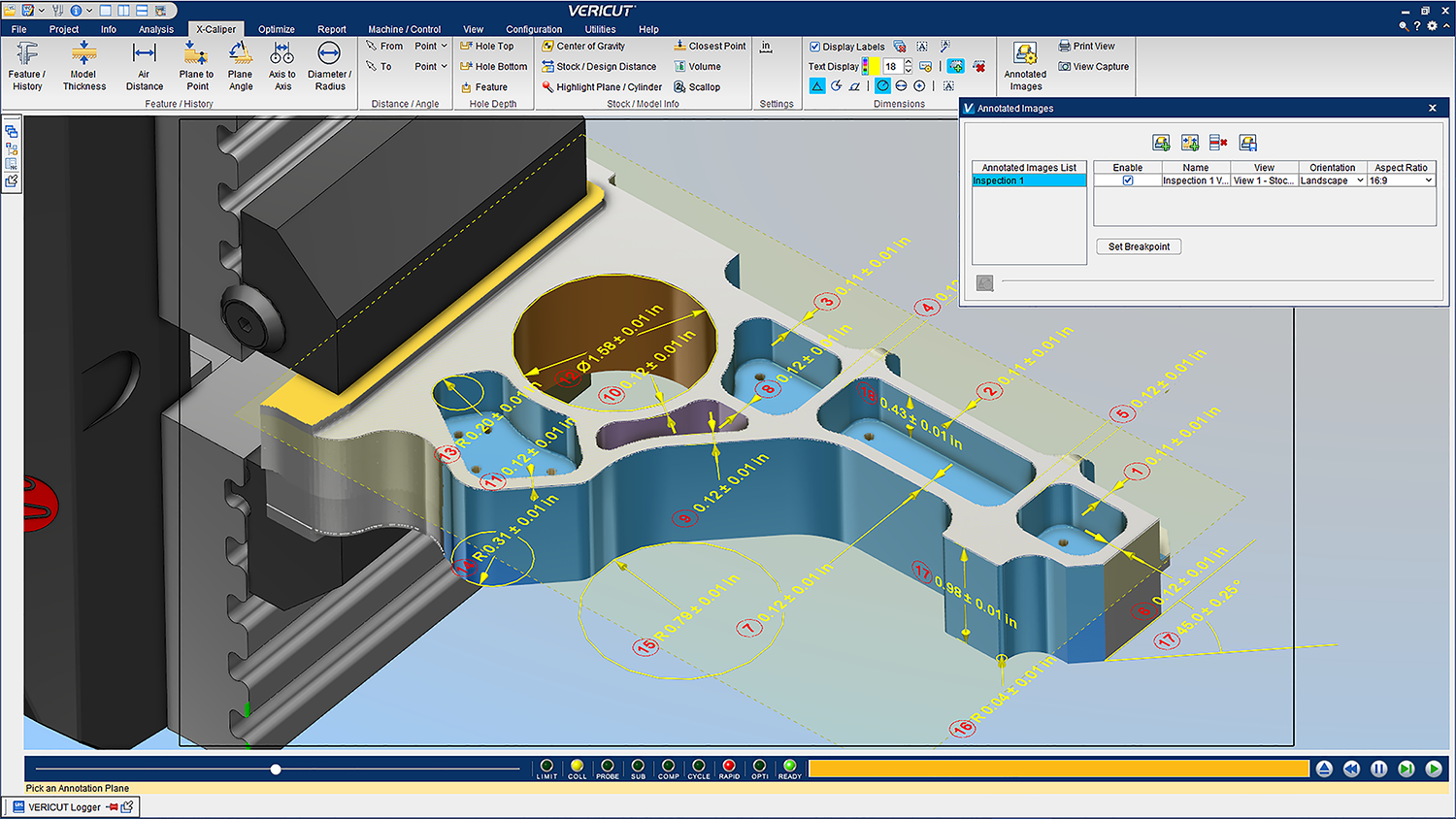

Within the Farnborough Aerospace Consortium (FAC), members represent the pinnacle of UK advanced manufacturing capability. These companies require sophisticated technological solutions that not only eliminate production risk but also drive efficiency and capacity gains. CGTech, established in 1988, has risen to become the international standard for CNC simulation, verification, optimization, and analysis. The VERICUT software suite is its flagship solution, built upon a foundational concept vital to Industry 4.0: the creation of an identical digital twin of the physical machine environment. This digital asset, encompassing kinematics, controllers, fixtures, and tooling, serves as the essential bedrock for mitigating hazards and maximizing throughput in complex component manufacturing. This strategic approach transforms NC programming from a risky, trial-and-error process into a predictable, scientifically validated operation.

VERICUT Verification: Eliminating Risk Through Identical Emulation

The Technical Distinction: Simulation vs. Emulation

A core challenge in the digital manufacturing thread is the inherent gap between the Computer-Aided Manufacturing (CAM) system output and the commands ultimately executed by the machine tool controller. Many verification processes simulate the geometry dictated by the CAM system, yet they fail to account for the unique characteristics and potential errors introduced during post-processing and control logic interpretation—the precise set of instructions defined in the G-code.

VERICUT addresses this critical vulnerability by moving beyond simple simulation into identical emulation. The Verification module is specifically designed to remove risk by reading and simulating the exact post-processed G-code that will run on the machine. This distinction is crucial for aerospace parts, which frequently involve complex multi-axis simultaneous motions dictated by intricate control logic.

The software offers total G-code support, meaning it accurately emulates all CNC machine G-code and control logic. This fidelity ensures that the digital simulation behaves identically to the physical machine on the shop floor, eliminating a major variable that traditional simulation methods often overlook. Relying on the actual G-code achieves a state of post-processor confidence, guaranteeing that the machine’s complex behavior is predicted accurately every single time. This is especially vital when developing complex cycles where vendor-specific control logic dictates critical movement paths.

Mitigating Catastrophic Failure and Downtime

The tireless function of VERICUT Verification is to inform manufacturers of any possible errors or collisions within the CNC machining setup before the job is released. By detecting these errors fast, VERICUT prevents unexpected events that cause catastrophic machine damage and production halts. Manufacturers incur enormous costs from collisions, not only due to the repair expenses for multi-million-pound machine platforms but also from the associated production downtime.

The operational impact of guaranteed digital verification is profound: it eliminates the need for manual prove-outs. Manual prove-outs are highly resource-intensive, requiring valuable machine time, operator presence, and carrying the inherent risk of tooling breakage or scrapping expensive raw material. By removing these resource drains, VERICUT ensures that when the verified NC program hits the shop floor, manufacturing personnel can be confident it is programmed correctly, allowing for lights-out or unattended operations and preventing unplanned downtime prior to actual cutting.

Scalability through Advanced Modules

The Verification platform provides a comprehensive and scalable foundation capable of addressing all complexity levels in aerospace machining. This platform can be bolstered by a range of supplementary modules, such as Multi-Axis verification, which ensures that even the most demanding 5-axis, turn-mill, and complex multi-plane applications are comprehensively checked for potential errors at both the workpiece and the tool. This modular approach ensures that the digital verification solution grows in complexity alongside the manufacturer’s technical capabilities and contract requirements.

The Physics of Productivity: VERICUT Force Optimization

Once manufacturing safety and collision avoidance are digitally guaranteed through Verification, the next strategic goal is the maximization of efficiency. This critical shift is addressed by VERICUT Force, a physics-based NC program optimization software module designed to analyze tool paths and machining conditions to aggressively reduce machining times.

The Shift to Physics-Based Strategy

Conventional optimization often relies on empirical data or simple feed-rate overrides that fail to account for the actual forces exerted on the cutting tool and machine spindle in real-time. Force optimization adopts a scientific approach, using advanced physics modeling to manage the dynamic interaction between the tool and the workpiece material.

Force expertly calculates the contact area and dynamic forces between the tool and material, allowing it to adjust feed rates dynamically for optimal performance. The core technical mechanism involves sophisticated block break-up, where the software dynamically calculates new program feed rates to remove material using a constant, ideal chip thickness, regardless of the geometry being cut.

This process simultaneously limits excessive cutting forces and spindle power requirements, matching the exact cutting conditions to the cutting tool's performance parameters. The result is a more consistent chip thickness throughout the machining process, which significantly enhances cutting tool performance and longevity. By moving away from conventional trial-and-error optimization, Force establishes maximum, consistent material removal rates (MRR), transforming high-variance cutting processes into predictable, high-speed operations.

The Quantitative Leap in Aerospace Throughput

The direct benefit of physics-based optimization is a dramatic reduction in machine cycle time. VERICUT Force typically slashes cycle times by up to 25% across various industries. For the aerospace sector, where parts are often large, complex, and involve cycles lasting many hours, this time saving translates into significant latent capacity gain.

For instance, one long-running aerospace component requiring a 125-hour cycle time was projected to save 30 to 40 hours using Force optimization. This degree of capacity liberation allows manufacturers to increase throughput and accept additional contracts without requiring new capital investment in machine tools. Furthermore, by protecting tools from unnecessary and excessive cutting forces, Force can preserve and extend tool life by up to two times, with some users reporting increases of 150-200% on specific machining operations. This further minimizes tooling costs and maximizes machine uptime.

The analytical rigor supporting this optimization is provided by the optional Force Analysis module. This module allows engineers to visualize the cutter-material interaction graphically, displaying key data points block by block. This provides crucial information for process refinement, particularly when developing robust strategies for exotic and difficult-to-machine alloys.

VERICUT Force Optimization: Key Analytical Parameters

Analysis CategoryKey Parameters Measured/OptimizedRelevance to Aerospace MachiningCutting DynamicsChip Thickness, Feed Per Tooth, Volume Removal RateEnsures high Material Removal Rate (MRR) without overloading the tool, crucial for demanding exotic alloys.Tool & Machine LoadTotal Force, Torque and Power, Spindle SpeedProtects high-cost machine spindle and structural components by limiting excessive and damaging loads.

Geometrical IntegrityContact Area, DeflectionMinimizes tool deflection and vibration, critical for achieving stringent aerospace surface finish and tolerance requirements.

Specialised Solutions for Advanced Materials and Processes: The Composite Revolution

The development and production of lightweight composite structures—essential components of modern aircraft—present unique manufacturing and quality challenges. VERICUT extends its core verification and programming principles to address Automated Fiber Placement (AFP) and Automated Tape Laying (ATL) processes through specialized Composite Software modules.

Extending the Digital Twin to Additive Layering

In composite manufacturing, defects are often structural and insidious, compromising the integrity of the finished part before it leaves the layup machine. Vericut Composite Simulation (VCS) and Vericut Composite Programming (VCP) establish the necessary digital thread for these processes, where the verification goal shifts from preventing external mechanical collisions to preventing internal, structural flaws.

VERICUT Composite Simulation (VCS): Quality Assurance for Layers

VCS is the simulation module designed to read, validate, and simulate the NC programs that will run on the layup equipment. It is capable of simulating upwards of 500 individual composite fiber layers. This hyper-accurate simulation capability ensures that each piece of the layer stack is positioned exactly for optimal cutting performance.

VCS is critical for validating process parameters and quality control. It expertly verifies compaction roller conformance, form conformance, material orientation, path correctness, layering sequences, and compaction axis travel. Crucially, VCS measures and inspects added material for critical defects such as overlaps or gap areas, which could result in a faulty run, a scrapped component, or a structurally compromised part. By alerting operators if the composite piece, tool path, or cutting geometry gets too close to machine obstacles, VCS minimizes the chance of a costly collision or machine crash, minimizing material waste in extremely high-cost materials. This shifts quality inspection from expensive, often destructive, post-process testing to proactive digital verification.

VERICUT Composite Programming (VCP): Streamlining the Workflow

While VCS focuses on verification, VCP automates the programming workflow for composite manufacturing. VCP enables the generation of optimized NC code for layup machines, streamlining processes that were traditionally time-consuming and labor-intensive manual tasks.

VCP allows composite part designers to maintain complete control over their components, enabling rapid creation and experimentation with various AFP path options. Engineers can measure and evaluate the effects of material steering, path trajectory, surface curvature, and other process constraints before generating robust NC code suitable for any machine vendor, including Electroimpact and MTorres. The ability to handle complex ply information, surface models, and geometries from major CAD programs ensures that VCP seamlessly integrates into the digital design environment.

Strategic Business Benefits and the Sustainability Angle

The integration of VERICUT's verification, optimization, and composite capabilities delivers a holistic economic return that spans the entire manufacturing lifecycle.

The Financial Impact of Digital Trust

The synergistic effect of Verification and Force generates measurable financial benefits. Verification guarantees process safety by eliminating machine damage and high-value scrap parts. Optimization, through Force, liberates machine capacity by achieving significantly faster cycle times. The resulting return on investment (ROI) is multi-fold. By providing absolute digital confidence, VERICUT empowers design engineers to be more creative and pursue challenging, complex geometries without the crippling fear of production failure, ultimately leading to better-performing aircraft components. Furthermore, the reliable virtual simulation eliminates manual prove-outs, ensuring that capacity is maximized for production rather than preparation.

VERICUT also provides crucial benefits when scaling production. Manufacturers can simulate, validate, and optimize a single part and reliably scale the resulting efficient process to large batches in low-mix, high-volume manufacturing environments, ensuring immediate cost savings across the entire production run.

Linking Efficiency to Sustainability (ESG)

Beyond direct financial and capacity benefits, the efficiency gains driven by VERICUT Force translate directly into measurable sustainability dividends, supporting modern Environmental, Social, and Governance (ESG) mandates.

Physics-based optimization reduces the machine run time required to produce a component. This reduction in spindle engagement time inherently reduces overall energy consumption and the spindle power required to cut the raw material. Manufacturing efficiency is thus linked directly to environmental responsibility. For FAC members seeking to showcase responsible manufacturing practices, VERICUT provides a technological path to achieve and report quantifiable reductions in energy usage per manufactured part, delivering a competitive edge in a global market increasingly prioritizing sustainability.

Conclusion: Partnering for the Future of Flight

CGTech’s VERICUT software is an indispensable tool for the advanced aerospace supply chain, offering an integrated solution that mitigates catastrophic risk while fundamentally boosting operational efficiency. The strategic investment lies in leveraging VERICUT’s capability to function as a flawless digital twin. This fidelity allows manufacturers to confidently verify the exact G-code execution, apply physics-based optimization to maximize throughput and tool life, and ensure the structural quality of complex composite structures.

For members of the Farnborough Aerospace Consortium, deploying VERICUT is a strategic step toward maximizing latent machine capacity, eliminating production uncertainty, and achieving world-class efficiencies necessary to meet the demanding technological and compliance requirements of the future of flight.

FAC members interested in realizing these measurable capacity gains and risk reductions are encouraged to connect directly with the CGTech UK team. Contact information is available via phone at 01273 773538 or by emailing info.uk@cgtech.com.

Sources used in the report

Reduce CNC Machining Costs With Four Proven Strategies - Vericut USA

Opens in a new windowvericut.com

Vericut 9.3 for VCS & VCP Composite Applications

Opens in a new windowvericut.com

Vericut Force - CNC Optimization Software - Vericut USA

Opens in a new windowvericut.com

Vericut Verification - CNC Verification Software - Vericut USA

Opens in a new windowvericut.com

Composite Simulation Software (VCS) - Vericut USA

Opens in a new windowvericut.com

Opens in a new windowvericut.com

Composite Software - Vericut USA

Opens in a new windowvericut.com

Composite Applications - Vericut's

Opens in a new windowvericut.com

Composite Programming Software (VCP) - Vericut USA

Opens in a new windowvericut.com