ROLLS ROYCE & ULTRAFAN

FAC FEATURE

Rolls-Royce, a global leader in power and propulsion, continues its innovation legacy with the revolutionary Ultrafan engine. This technology demonstrator, the world's largest aero-engine at 140 inches in diameter, offers up to 25% better fuel efficiency than previous Trent engines. Successfully tested on 100% Sustainable Aviation Fuel (SAF), Ultrafan underscores Rolls-Royce’s commitment to sustainable aviation and pioneering next-generation propulsion solutions for future aircraft, crucial for achieving net-zero by 2050.

Rolls-Royce, a name synonymous with engineering excellence and innovation, continues to push the boundaries of propulsion technology. For over a century, the British multinational company has been at the forefront of developing complex power and propulsion solutions for critical applications in air, sea, and land [intro]. In recent years, its commitment to research and development has culminated in a groundbreaking project set to redefine commercial aviation: the Ultrafan engine.

Rolls-Royce: A Legacy of Innovation

Rolls-Royce's history is marked by continuous innovation, from its early forays into aerospace during World War I with the Eagle engine to the iconic Merlin engine that powered legendary aircraft like the Supermarine Spitfire [intro]. The company solidified its position in commercial aviation with the RB211 engine in the 1960s and 70s, which introduced the high-bypass turbine, now a standard in modern commercial aviation. This legacy of pioneering breakthroughs, particularly the triple-spool design adopted in the successful Trent engine family, has cemented Rolls-Royce's reputation as a leader in aviation technology [intro]. The company invests heavily in technology, integration capabilities, and facility modernisation, underscoring its role as a persistent innovator [intro]. Rolls-Royce's R&D expenditure was £923m in 2010.

The company also maintains a significant global research network, collaborating with universities and technology centres worldwide. This includes Advanced Manufacturing Research Centres (AMRC) in Sheffield for machining and measurement, the Manufacturing Technology Centre (MTC) in Ansty for automation, fixturing, and joining, and the National Composites Centre (NCC) in the South West for composite materials. These partnerships are crucial for developing long-term capabilities and recruiting skilled personnel.

Rolls-Royce has been active in the nuclear supply chain for over 50 years and manages over 300 certified nuclear suppliers. Its nuclear capabilities extend to submarine systems, reactor design and supply, licensed site operation, fuel fabrication, and through-life services. Rolls-Royce also has major sites in the UK (such as Derby and Bristol) and Germany. International collaboration is vital for sharing risk and costs in developing new technologies and components.

The Ultrafan Engine: A Step-Change in Efficiency

The Ultrafan engine stands as Rolls-Royce's latest and most formidable innovation, representing a significant leap forward in engine design and sustainability [intro]. Publicly unveiled in 2014 [intro, 230, 262, 287], the Ultrafan is the world's largest aero-engine technology demonstrator, featuring a remarkable 140-inch (3.5-meter) fan diameter—larger than any other jet engine built to date [intro, 41, 266, 327, 376].

This revolutionary engine incorporates a suite of new technologies designed for greater fuel efficiency, lower emissions, and enhanced sustainability [intro, 374]. Key innovations include:

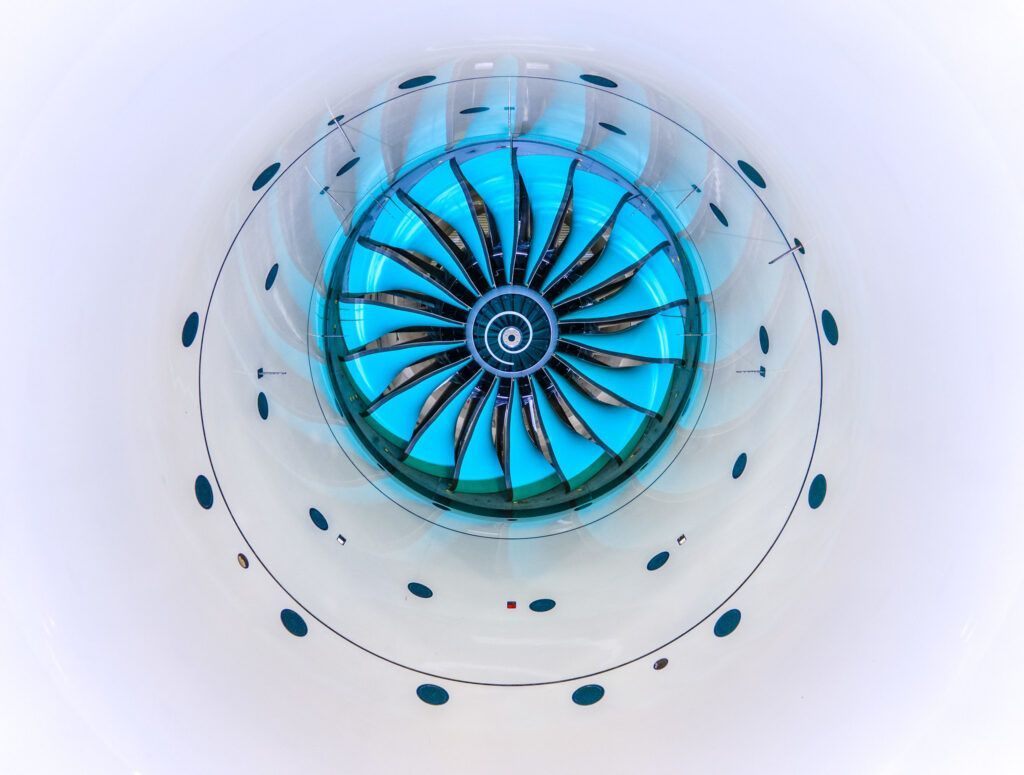

- Geared Architecture: Unlike traditional fixed-pitch fan systems, the Ultrafan features a geared design that allows the engine’s fan to operate at a slower, optimal speed while the compressor and turbine spin faster, significantly increasing efficiency and reducing noise [intro, 264, 363]. This fundamentally different design architecture is a first for Rolls-Royce at this scale [intro]. The bespoke power gearbox handles an immense 64 megawatts (86,000 horsepower) of power, an aerospace record [intro, 266]. This gearbox was transferred from Dahlewitz, Germany, to Rolls-Royce's UK site for assembly in March 2022.

- Advanced Materials: To achieve impressive weight reductions and withstand extreme operating conditions, the Ultrafan extensively uses lightweight carbon composite fan blades augmented with thin titanium edges [intro, 41, 264, 266, 301, 306, 364, 375, 397, 418]. These blades are manufactured by accumulating hundreds of layers of carbon fibre and resin under heat and pressure, with the titanium leading edge providing extreme protection against erosion, foreign objects, and bird strikes. This composite fan system reduces the weight on a twin-engine aircraft by 700 kg (1,500 lb). The blades were created at Rolls-Royce's Bristol centre of excellence for composite technology, using an automated tape layup system, and have been extensively tested on an Advanced Low Pressure System (ALPS) development engine, including in-flight testing on the Rolls-Royce Flying Test Bed. The engine also incorporates advanced ceramic matrix composite (CMC) components in the high-pressure turbine, allowing for more effective operation at higher temperatures and pressures.

- New Core Architecture: The Ultrafan integrates the Advance3 engine core, a revolutionary new core design utilising Rolls-Royce's three-shaft architecture to deliver maximum fuel burn efficiency and low emissions [intro, 263, 374]. It also features the ALECSys (Advanced Low Emissions Combustion System) lean burn combustor, which has undergone extensive testing on 100% Sustainable Aviation Fuel (SAF) [intro, 374].

- Variable Pitch Fan System: This system allows the fan blades to vary their pitch to optimise for each flight phase, eliminating the need for a thrust reverser and contributing to reduced weight and drag [intro, 264, 397].

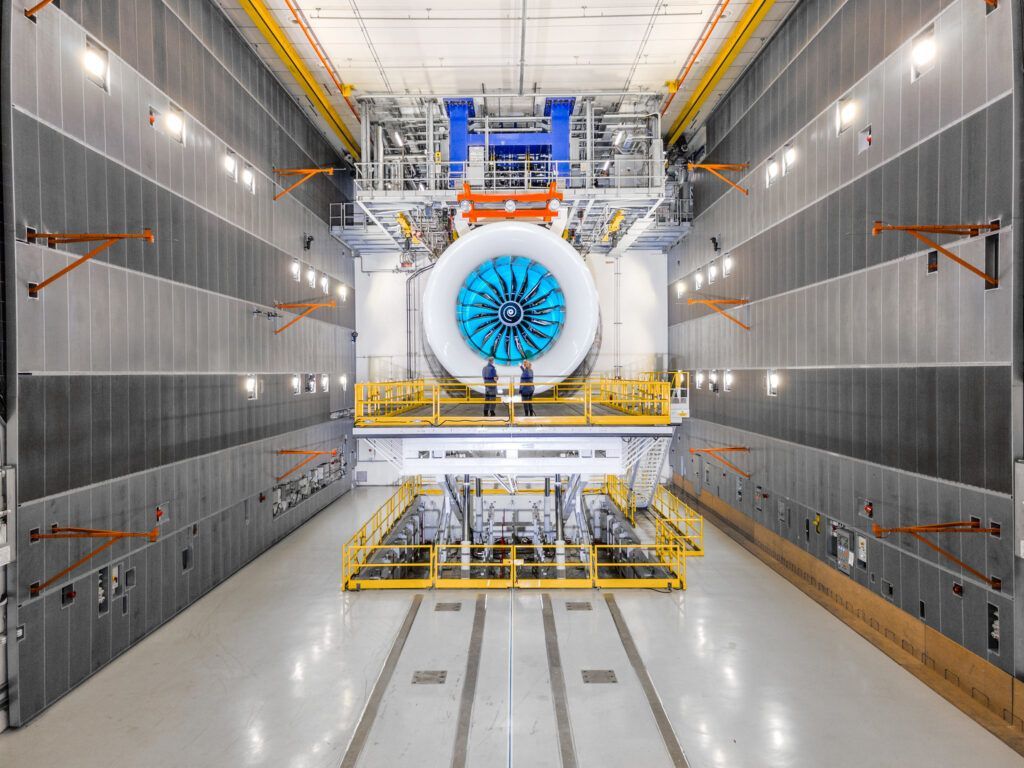

The development journey of the Ultrafan has spanned a decade, with work officially commencing at its DemoWorks facility in Derby, UK. Its first static tests took place in May 2023 at Rolls-Royce's dedicated £90 million Testbed 80 facility in Derby, UK [intro, 225, 310, 333, 365, 379, 419]. These initial tests were conducted using 100% Sustainable Aviation Fuel (SAF), underscoring the engine's readiness for future sustainable aviation [intro, 292, 310, 333, 391, 398, 440]. In November 2023, the Ultrafan demonstrator achieved a significant milestone by successfully running to its maximum power, surpassing 85,000 pounds of thrust and performing in line with expectations [intro, 225, 309, 310, 391, 403]. ITP Aero, a corporate entity within the Rolls-Royce group, played a crucial role in delivering the first Ultrafan Intermediate Pressure Turbine (IPT) from its assembly facility in Ajalvir (Madrid), which was then assembled at Rolls-Royce’s Derby facilities [intro, 34]. The MTC (Manufacturing Technology Centre) collaboratively designed, set up, and operated an additive manufacturing pre-production facility that supplied all of the titanium engine section stator (EES) components required for the Ultrafan™ engine development programme, using Electron Beam Melting (EBM) as the lead technology. WDB Ltd also supported the Ultrafan project by balancing fast-make development parts with quick turnaround times for the testing programme. Testbed 80 is the world's largest indoor aero-engine facility, purpose-designed for industrial radiography, with robust protection against X-ray emissions and acoustic insulation. It can collect data from over 10,000 parameters at rates up to 200,000 samples per second.

Impact and Potential of Ultrafan

The Ultrafan's impact on the aviation industry is projected to be transformative:

- Unprecedented Efficiency: The engine is designed to be 25% more fuel-efficient than the first generation of Trent engines [intro, 230, 328, 363, 397] and offers a 10% efficiency improvement over the Trent XWB, currently the world’s most efficient large aero-engine in service [intro, 333, 398, 399, 418]. This translates to billions of dollars in fuel savings for airlines [intro, 418].

- Environmental Benefits: Beyond fuel efficiency, the Ultrafan is engineered to significantly reduce CO2 emissions, cut nitrogen oxide (NOx) emissions by 40%, and lower noise levels by 35% [intro, 398, 419]. Its compatibility with 100% SAF from day one is critical for achieving the industry's target of net-zero flight by 2050 [intro, 292, 310, 333, 391, 398, 440]. The shift to greener technologies is also driven by increasingly strict government regulations.

- Scalability and Versatility: The Ultrafan's scalable technology, with a thrust range from approximately 25,000 to 110,000 pounds, offers the potential to power new narrowbody and widebody aircraft anticipated in the 2030s [intro, 301, 306, 418, 422]. Rolls-Royce is actively planning a smaller variant, the Ultrafan 30, with a fan diameter of about 90 inches, specifically to re-enter the narrow-body jet engine market for aircraft replacing the Boeing 737 and Airbus A320 [intro, 114, 416].

- Transferable Technologies: Rolls-Royce plans to transfer various technologies developed for the Ultrafan programme to its current Trent engines, offering incremental improvements in availability, reliability, and efficiency in the nearer term [intro, 301, 306, 311, 398, 399, 440].

- Future Energy Options: The Ultrafan provides a flexible platform for diverse energy options, including current jet fuel, sustainable aviation fuels, and future potential for hybrid-electric and hydrogen power solutions [intro, 286, 372, 373, 440]. Rolls-Royce is actively exploring hybrid-electric systems, having tested its Power Generation System 1 (PGS1) to beyond 1.5MW in Trondheim, Norway, and Bristol, UK, and has ambitions to move these to a flight test phase. The company is also committed to understanding hydrogen power systems, partnering with easyJet for a comprehensive research programme of rig and engine tests at MoD Boscombe Down, UK, aiming for small-mid size aircraft from the mid-2030s.

Rolls-Royce: A Continuous Innovator

The Ultrafan program is a testament to Rolls-Royce's unwavering commitment to pioneering technology and sustainable solutions [intro]. Supported by the UK Government through the Aerospace Technology Institute (ATI), Innovate UK, Germany’s LuFo, and the EU’s Clean Sky programmes, this initiative is a collaborative effort to deliver transformative technology [intro, 287, 293, 365, 378, 393]. Airbus and Rolls-Royce have a collaboration agreement for the integration of the Ultrafan demonstrator for flight testing, co-funded by Clean Sky 2.

Beyond the Ultrafan, Rolls-Royce's innovative spirit extends to other areas, such as its "IntelligentEngine" vision, which integrates products, services, and digital technology [intro, 294, 349, 350, 351]. The company is also developing advanced technologies for servicing and maintenance through projects like REINSTATE, aiming to reduce waste and emissions by enabling "key-hole surgery" for engines and repairing complex parts [intro, 276, 278, 279]. This involves developing "snake robots" to access complex parts, sensors for predictive maintenance, inspection tools for buried components, and advanced automated repair technologies. These technologies will be deployed on existing engines and adapted for future low-carbon engines.

Rolls-Royce is also advancing its "Digital Future" and "Digital Twin" concepts, especially for defence applications. This involves transforming engineering processes through digital innovation to deliver solutions faster and more cost-competitively, reducing the need for physical manufacturing and testing. Digital design models, calibrated with real-world data, ensure accuracy and trust, allowing for virtual modelling and simulation at unprecedented speeds and aiming for zero defects. A digitally interconnected network of suppliers has real-time access to standard features and manufacturing data through a collaboration portal, ensuring design changes flow rapidly and aiming for zero defects in manufacturing and assembly.

Furthermore, Rolls-Royce is making significant strides in nuclear energy. It has extensive nuclear capabilities, including submarine systems, reactor design, licensed site operation, and fuel fabrication. The company has been selected to deliver Small Modular Reactors (SMRs) for the UK and plans to expand into the US market, showcasing its capability in advanced nuclear technologies and commitment to a "Golden Age" of nuclear energy [intro, 47, 344, 345]. In March 2023, the UK Space Agency funded Rolls-Royce to create a nuclear reactor for the moon, intended to power space missions. Rolls-Royce is recognized as the only company globally with full lifecycle experience, end-to-end capability, and an established supply chain in the nuclear sector.

Recent commercial successes further highlight Rolls-Royce's position. At the 2025 International Paris Air Show, the company secured contracts for 90 Trent XWB-97 engines, 40 Trent 7000 engines, and 12 Trent XWB-84 engines from airlines in Saudi Arabia, Egypt, Taiwan, and Vietnam, safeguarding jobs in Derby well into the 2030s.

In conclusion, the Rolls-Royce Ultrafan engine is not merely a new product; it is a declaration of the company's enduring dedication to innovation, sustainability, and shaping the future of global aviation [intro]. Its advanced architecture, cutting-edge materials, and remarkable efficiency gains demonstrate Rolls-Royce's leadership in an industry striving for a net-zero future, setting a new benchmark for performance and environmental responsibility [intro].

Report Sources

- 1-Sectoral-Analyses-Aerospace-Report (1).pdf

- Aerospace Pre-Production - Rolls Royce Ultrafan™ Development

- Aircraft & Airplane Engines | Rolls-Royce Civil & Defense Aerospace | Aviation

- defence-excellence.pdf

- edu-neil-takei-session4-en.pdf

- ITP Aero delivers the first UltraFan Intermediate Pressure Turbine to Rolls-Royce – Fabricante de motores aeronáuticos y turbinas

- Press releases | Rolls-Royce

- rr-defence-factsheet.pdf

- Rolls Royce - The Jet Engine.pdf

- Rolls-Royce Achieves Major Milestone, Running UltraFan Demonstrator At Full Power — Born To Engineer

- Rolls-Royce Announce Next Generation of Engine Technology Design - ADS Group

- Rolls-Royce announce innovative new project - ADS Group

- Rolls-Royce: Delivering complex power solutions | Rolls-Royce

- Rolls-Royce Holdings - Wikipedia

- Rolls-Royce in final build phase for UltraFan demonstrator - AGN

- Rolls-Royce officially begins work on UltraFan aero engine

- Rolls-Royce runs UltraFan engine at full power | Aerospace Testing International

- Rolls-Royce runs UltraFan tech to the max - ADS Advance

- Rolls-Royce Says UltraFan Engine is ‘Bristling’ with New Technology | Aviation International News

- Rolls-Royce secures international deals for 142 aircraft engines - BBC News

- Rolls-Royce starts making 'world’s largest fan blades' for revolutionary new aero engine - Business Live

- Rolls-Royce tests 'game-changing' greener UltraFan engine technology - BBC News

- Rolls-Royce Trent - Wikipedia

- Rolls-Royce Ultrafan: The future of commercial aviation | WDB Group

- Rolls-Royce welcomes action from UK and US Governments to usher in new ‘Golden Age’ of nuclear energy | Rolls-Royce

- Rolls-Royce | The Power of Digital Innovation in Defence (YouTube transcript)

- taieb-ben-sghaier-rolls-royce-11112015.pdf

- This new Rolls-Royce Engine is Coming & will Revolutionize the Aviation Industry! (YouTube transcript)

- UltraFan | Rolls-Royce

- UltraFan on test marks a step-change in ultra-efficient engine technology - Aerospace Technology Institute

- UltraFan: Rolls-Royce's World's Largest Aero-engine Demonstrator

- ultrafan-fact-sheet.pdf

- Very High By Pass | Clean Aviation

- Why Might The World's Largest Aircraft Engine Have Boeing Worried?

- World's largest and most efficient aircraft engine aces first tests

- TIERNEY Chris_Rolls-Royce NEA - 5 Nov 2018 Issue 1.pdf