HUMANOID ROBOTICS IN MANUFACTURING

FAC TECHNOLOGY FEATURE

Imagine walking onto a factory floor where the newest hire isn’t wearing safety boots, doesn’t take coffee breaks, and just happens to be made of metal and silicon. We are no longer looking at a distant sci-fi future; we are witnessing the dawn of the "robotic coworker"—a machine built not just to assemble, but to adapt, walk, and work alongside us in the aisles we built for ourselves. From relieving humans of dangerous heavy lifting to solving chronic labor shortages, these humanoid robots promise to unlock a level of flexibility and efficiency that traditional automation could only dream of.

DATELINE: SILICON VALLEY & DETROIT — For decades, the image of factory automation has been consistent: massive, heavy-duty articulated arms bolted to concrete floors, welding car chassis or moving heavy pallets inside safety cages. They are efficient, strong, and incredibly fast. But they are also rigid. If you move a part three inches to the left, the traditional robot fails.

The manufacturing sector is now facing a dual challenge: a chronic global labor shortage for repetitive manual tasks and a need for hyper-flexible production lines that can change products rapidly.

Enter the general-purpose humanoid robot.

We are no longer talking about sci-fi concepts or delicate research projects that fall over if nudged. We are witnessing the birth of a new industrial workforce designed to operate in the only environment that matters: the one already built for humans.

The "Brownfield" Advantage: Why Humanoids?

The primary argument for humanoid robots in manufacturing is not mere novelty; it is compatibility.

The vast majority of the world’s factories are "brownfield" sites—existing facilities designed with aisles, stairs, doorways, workstations, and tools optimized for the human form. Ripping these facilities apart to accommodate wheeled robots or entirely automated dark factories is cost-prohibitive.

Humanoid robots are being developed to slot seamlessly into these existing environments. Their value proposition rests on three pillars:

- Mobility in Unstructured Spaces: Unlike Automated Guided Vehicles (AGVs) that require magnetic tape or predefined paths, humanoids can walk over cables, navigate tight corners, step up curbs, and crouch under conveyors.

- Dexterous Manipulation: Using advanced AI and multi-fingered hands, these robots are learning to grasp tools designed for humans—power drills, scanners, and tote handles—rather than requiring custom end-effectors for every new task.

- The "Gap Filler" Role: They excel at tasks that sit between manual labor and full automation. This includes "machine tending" (loading/unloading a CNC machine), moving parts between disparate conveyor belts, or performing end-of-line quality checks that require walking around a finished product.

The Titans of the New Workforce: Top 3 Global Leaders

While many startups are entering the fray (Agility Robotics, Apptronik, Sanctuary AI), three companies currently dominate the headlines regarding capital, technological maturity, and viable paths to manufacturing deployment.

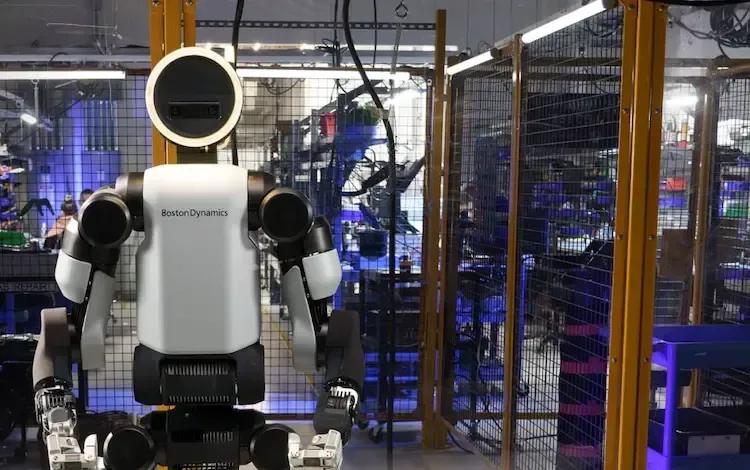

1. Boston Dynamics (The Pioneer Pivoting to Production)

For years, Boston Dynamics was the viral video king of R&D robotics. Their hydraulic Atlas robot could do backflips and parkour, pushing the boundaries of dynamic balance. However, critics often noted it lacked a commercial application.

That changed recently. Boston Dynamics retired their hydraulic Atlas and immediately unveiled a fully electric commercial version.

- The Manufacturing Angle: The new electric Atlas is quieter, stronger, and designed for practical application rather than acrobatics. Boston Dynamics is leveraging decades of data on bipedal locomotion to create a robot that can handle heavy lifting and complex maneuvering in industrial settings.

- Current Status: They are aggressively moving toward commercialization, targeting heavy industries and logistics where their robots' superior strength and balance give them an edge.

2. Tesla (Optimus – The Scale Specialist). When Elon Musk announced the Tesla Bot (now Optimus) in 2021 with a dancer in a suit, many dismissed it as a sideshow. Few are laughing now.

Tesla possesses two unique advantages that no other robotics company has: a massive, in-house manufacturing base to serve as a testbed, and the world's largest real-world AI training pipeline derived from its Full Self-Driving (FSD) vehicle data.

- The Manufacturing Angle: Tesla is designing Optimus specifically to work inside Tesla Gigafactories. They are already testing early prototypes performing tasks like moving battery cells. Musk’s goal is to create a general-purpose laborer that is mass-producible—building the robot like a car.

- Current Status: Iteration is rapid. Optimus Gen 2 shows significantly improved dexterity and fluidity. Tesla’s strategy is vertical integration: build the brain, build the body, and own the factory where it works.

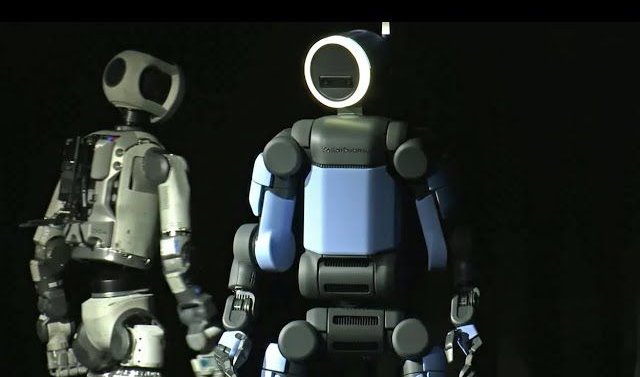

3. Figure AI (The Fast-Track Contender). Figure AI burst onto the scene with a singular, intense focus: deploying general-purpose humanoids into the workforce as fast as possible.

They have secured massive funding (a recent $675 million round valued them at $2.6 billion) from heavy hitters like Microsoft, Nvidia, and OpenAI.

- The Manufacturing Angle: Figure is not waiting for perfection. In early 2024, they announced a landmark commercial agreement with BMW Manufacturing. Figure’s robots will be deployed at BMW’s Spartanburg, SC facility—the largest BMW automotive exporter in the world. They will start by identifying dozens of specific use cases in body shop, sheet metal, and warehouse operations.

- Current Status: Figure is focused on speed-to-market and strategic partnerships, leveraging OpenAI’s models to give their robots high-level reasoning capabilities for complex tasks.

The Future Outlook: Timeline and Pricing Realities

When will you actually see a humanoid robot working alongside a person at your local plant? And how much will it cost? The answers require separating hype from reality.

The Realistic Timeline

We are currently in the "Pilot Phase" (2024–2026).

During this period, you will see headlines about BMW, Tesla, and Amazon deploying small numbers (5–50 units) of these robots. These are controlled tests. The robots will be slow, they will be heavily monitored, and they will perform very narrow tasks (e.g., moving a tote from point A to point B all day). The goal here is gathering real-world data and validating safety protocols.

The "Early Commercial Phase" (2027–2029):

If pilots are successful, we will see broader deployments in manufacturing hubs. Robots will begin handling more complex, multi-step tasks. They will likely still be segregated from dense human traffic for safety reasons.

The "General Purpose Phase" (2030 and beyond):

This is when the technology matures enough for widespread adoption across small and medium-sized enterprises (SMEs), with robots truly working shoulder-to-shoulder with humans without strict caging.

The Pricing Discussion

Pricing models for humanoid robots are currently highly speculative and evolving rapidly.

The "Musk Goal" (The Long Shot): Elon Musk has famously stated a long-term target price of under $20,000 for a Tesla Optimus—making it cheaper than a car. Most industry analysts view this as highly ambitious and likely a target for the 2030s, contingent on massive economies of scale.

The Realistic CapEx Model (Near Term): If you wanted to buy a highly capable humanoid robot outright today (if you could), estimates suggest a capital expenditure (CapEx) of anywhere between $150,000 to $250,000+ per unit. This pricing reflects the immense cost of advanced actuators, battery systems, and computing power.

The Likely Solution: Robots-as-a-Service (RaaS):

Because the upfront cost is prohibitive for many manufacturers, the dominant model in the near term will likely be Robots-as-a-Service (RaaS).

Instead of buying the robot, a factory will "hire" it for an hourly wage or monthly subscription, perhaps equivalent to $20–$30 per hour. This shifts the cost from CapEx to OpEx (operating expense), includes maintenance and software updates in the fee, and lowers the risk for the manufacturer trying out the technology.

Conclusion

The humanoid robotics revolution is no longer a question of "if," but "when." While we are years away from humanoids fully replacing human labor on assembly lines, the initial integration into factories has already begun. For manufacturers, the race is now on to determine how to integrate these new blue-collar workers into their future operations.