FAC FEATURED MEMBER

Innovating Condition Monitoring for Aerospace Reliability:

Full Matrix Ltd at a Glance

In an industry where safety, reliability, and predictive maintenance are mission-critical, Full Matrix Ltd stands out as an emerging technology partner capable of transforming how aerospace systems are inspected and monitored. Based in Cambridge, UK, this deep tech company designs and deploys advanced sensing systems that help operators detect issues before they impact performance — a capability that resonates strongly with aerospace engineering priorities.

At its core, Full Matrix specialises in ultrasonic sensor systems and condition monitoring technologies that tackle some of the most complex inspection and monitoring challenges seen in extreme and inaccessible environments. Originally founded to improve the safety of fusion powerplant infrastructure — environments with similarities to aerospace in terms of heat, vibration, and accessibility constraints — its multidisciplinary team brings expertise in engineering, physics, modelling, and machine learning to bear on real-world industrial problems.

Ultrasonics, EMATs, and Non-Destructive Testing

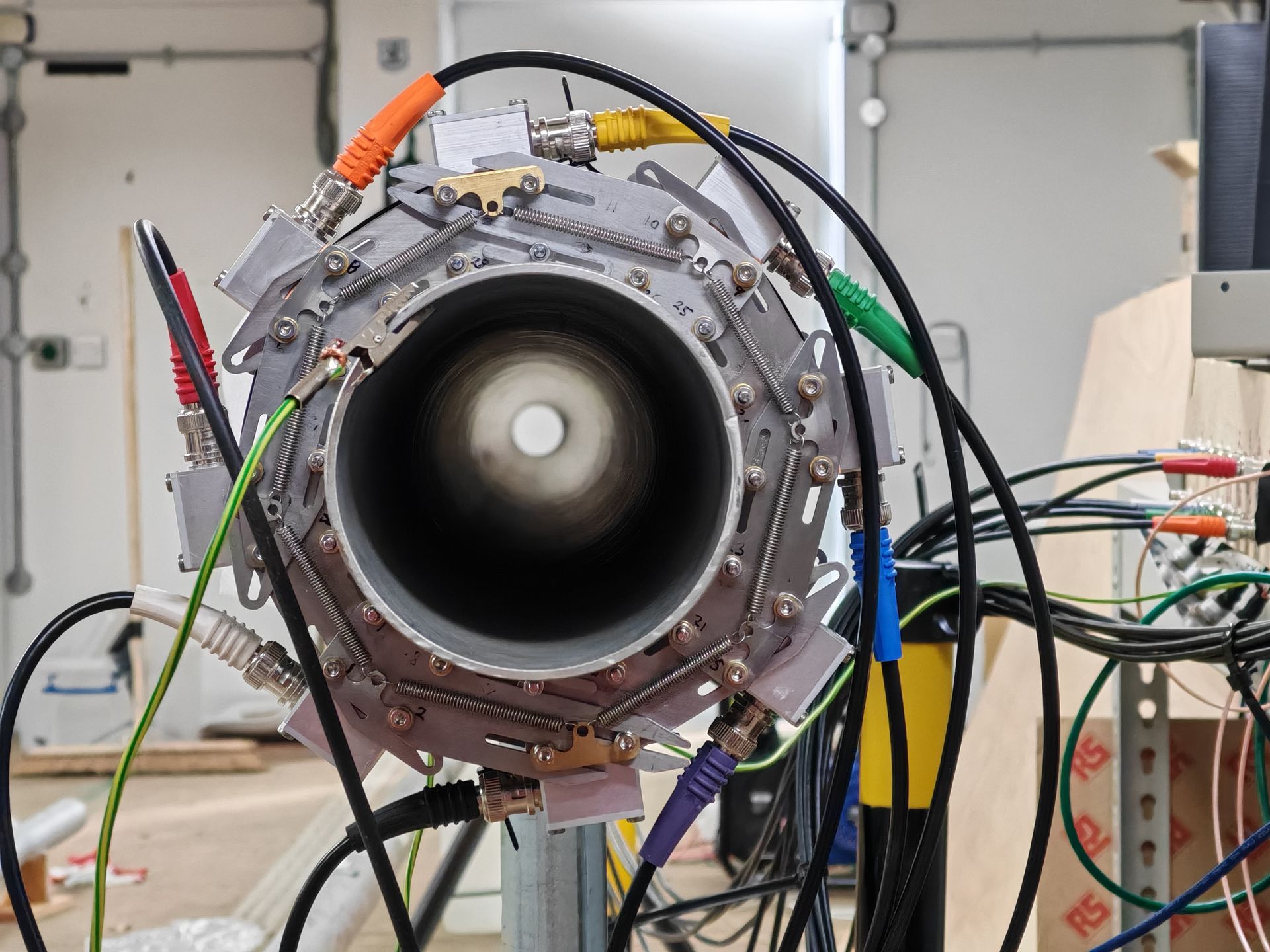

For aerospace applications — whether in engine components, landing gear assemblies, or airframe structures — robust non-destructive testing (NDT) is essential. Full Matrix’s strength lies in Electromagnetic Acoustic Transducers (EMATs) and low frequency ultrasonic technologies, which allow for high-fidelity inspection and monitoring without contact or disassembly. These systems can reveal internal defects, stress fractures, and material properties with minimal operational disruption — crucial for aerospace components where downtime is costly and safety margins are strict.

Their EMAT systems are engineered to withstand challenging field conditions and are supported by sophisticated array hardware. By optimising sensor configurations and leveraging advanced signal processing, these tools can be tailored to aerospace inspection regimes in aircraft and spacecraft structures.

AI, Modelling, and Digital Twins

Full Matrix goes beyond hardware with its emphasis on digital modelling and AI-driven analytics. The company integrates physics-based simulations with machine learning to generate digital twins — virtual representations of physical systems that evolve in real time based on sensor data. For aerospace engineering teams, this fusion of data and simulation will clarify where and when defects are developing, enabling maintenance to be scheduled proactively rather than reactively.

By incorporating uncertainty-aware insights, Full Matrix’s systems not only flag abnormalities but also provide interpretable outputs that align with engineering decision-making processes. This is particularly valuable for aerospace engineers tasked with certifying the airworthiness of parts and assemblies under strict regulatory standards.

Impact and Future Opportunities

Although Full Matrix has roots in energy and infrastructure sectors, its technologies have clear parallels to aerospace challenges — especially where access is restricted and safety margins are narrow. The company’s condition monitoring portfolio can complement existing aerospace NDT techniques such as eddy current, radiography, or laser-based scanning by offering remote or hard-to-reach sensing solutions that reduce downtime and enhance lifetime predictions.

Full Matrix’s vision is to become a trusted partner for monitoring complex assets, helping operators across industries predict failure before it happens, reduce risk, and plan maintenance proactively. For aerospace professionals committed to innovation and safety, these approaches aligns directly with industry goals around enhanced reliability and lifecycle optimisation.

Contact and Next Steps

Headquartered in Cambridge, UK, Full Matrix Ltd continues to expand its capabilities and collaborations. Aerospace teams interested in advanced condition monitoring solutions can explore partnerships that bring cutting-edge sensor and analytics technology into their inspection and maintenance workflows.